Here is a comprehensive guide to help you make an informed decision when buying airless spray gun and spray tips.

Airless Spray Gun Selection

When choosing an airless paint spray gun, you should carefully consider several factors to ensure that it meets your specific needs. Pressure is the first consideration. If you are using a high-pressure sprayer (5000 to 7000 PSI), you need a stainless steel spray gun to withstand the high pressure. For standard pressure sprayers (3000 to 3300 PSI), aluminum spray guns are usually sufficient. If you are using specialty coatings such as high-solids paint, waterproof coatings, or adhesives, a stainless steel spray gun is recommended because it is durable.

Filtration is another important aspect. Determine if you need a spray gun with a filter. Some coatings cannot be filtered because they will clog quickly, resulting in a loss of momentum and pressure. For thick materials like drywall compound paint, it is better to use a front-feed spray gun without a filter because it allows the paint to flow through and spray better.

Special features can enhance a spray gun's versatility. If you're working at high angles or in tight spaces, you can attach inline spray guns to extension poles, rods, and rollers to help you reach hard-to-reach areas. For thick coatings, consider a spray gun with an oversized barrel that provides a wider fluid channel.

Finally, comfort is a subjective but crucial factor. The spray gun should feel comfortable in your hand for long periods of time. Variables to consider include the angle of the spray gun, its weight, and the type of trigger (two-finger vs. four-finger).

Choosing an Airless Spray Nozzle

The nozzle is a critical component of an airless sprayer. It controls the amount of atomization of the paint and the width of the fan pattern. Knowing how to choose the right nozzle can help you achieve flawless, professional results every time.

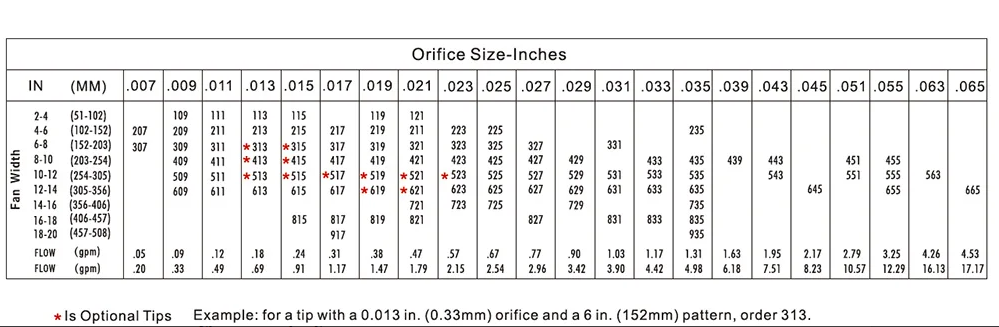

Airless spray nozzles are represented by three numbers. The first number represents the width of the fan pattern. Multiply this number by two to get the width of the nozzle fan pattern in inches and by five to get the width of the nozzle fan pattern in centimeters. The second two numbers represent the nozzle aperture in thousandths of an inch. The larger the aperture, the more paint will pass through.

The viscosity of the material being sprayed is a key factor in choosing the right nozzle size. Thin materials such as water-based sealers, varnishes, clearcoats, primers, and stains require smaller apertures. Medium viscosity materials such as oil-based enamels, latex, primer oils, clear acrylics, and primers require medium-sized apertures. Thick layers of materials such as smooth elastomers, heavy latex, polymers, anti-corrosion coatings, and heavy fillers require larger apertures. Very thick materials such as elastomers, block fillers, flame retardants, and anti-corrosion coatings require the largest apertures.