Air drills are versatile power tools that utilize compressed air to perform drilling and driving operations. They are commonly used in manufacturing, construction, auto repair. Air drills provide key advantages over traditional electric drills that make them well suited for professional use.

Why do air drills have advantages?

Lightweight - Air drills are much lighter than comparable electric drills, making them easier to handle and less tiring during prolonged use. Their lightweight nature also makes them ideal for tight, hard to reach spaces.

Safety - There is no danger of electric shock or fire because the drill is operated by air from the air compressor rather than from a high-voltage power outlet.

Power - Air drills pack a serious punch, delivering two to three times more torque than standard electric drills. This allows them to power through tough materials like steel, wood, and masonry with ease.

Variable Speed - Air drills feature variable speed triggers that allow you to dial in the precise RPM needed for the task. Slow speeds prevent stripping screws while high speeds bore through materials quickly.

Less Maintenance - Air drills require far less maintenance than electric alternatives. Just add air tool oil periodically to keep it running smoothly.

Durability - The simple inner workings and metal housing make air drills extremely durable tools built to withstand years of heavy use. They can handle accidental drops, vibration, dirt, and more.

Uses in Construction & Remodeling

For construction crews, air drills are a must-have tool. Drilling into concrete, brick, and other masonry. With specialized masonry drill bits, air drills make quick work of creating openings for electrical boxes, conduit, anchors, and tapcons in hardened materials. Their extra power drives big holes through solid concrete.

Driving self-feeding screws. Drywall crews use air drills with self-feeding screw tips for rapidly fastening gypsum board.

Mixing thinset and grout. Using a mixing paddle attachment, air drills can whip up mortar, thinset, and grout in a fraction of the time of mixing by hand. This saves huge effort on large tile jobs.

Automotive Uses

In auto repair shops, air drills are the cornerstone tool for working on vehicles.

Drilling holes. Air drills are perfect for drilling holes in metal, plastic, and other materials commonly found in vehicles. They can quickly and accurately create holes for bolts, screws, and other fasteners.

Reaming. Reaming is the process of enlarging or smoothing out existing holes. Air drills equipped with reamer bits are used to achieve precise hole diameters or to remove burrs and rough edges from a drilled hole.

Tapping threads. Air drills can tap threads into metal parts, allowing mechanics to install bolts, screws, and other fasteners securely.

Uses in Manufacturing & Metalworking

In manufacturing facilities and metal fabrication shops, air drills are essential for production and working with metal.

Drilling holes in metal. With heavy-duty cobalt bits, air drills drill production holes with extreme precision. Variable speed control prevents work hardening or damaging drill bits.

Installing self-tapping screws. Metalworkers use air drills with self-tapping screw tips for rapid assembly of materials or attaching gussets/brackets. The torque powers screws through thick steel.

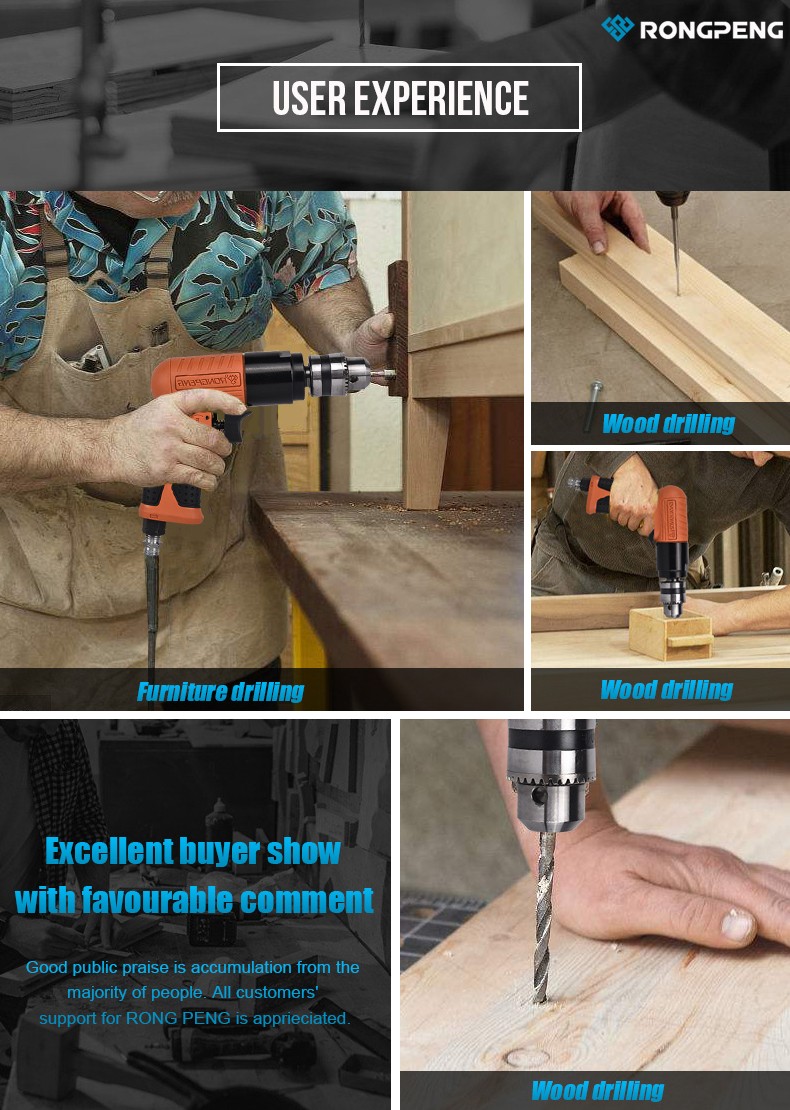

Woodworking Uses

For cabinet makers, woodworkers, and carpenters, air drills provide pinpoint precision along with added power for working with wood.

Drilling holes. Sharp point bits coupled with variable RPMs allow perfectly controlled hole drilling, great for pegboard holes or precisely aligned dowel joinery.

Mortising. Specialized mortising attachments cut precise square holes for mortise and tenon joinery with a sturdy guide.

Designed for professional use, the RONGPENG RP17101 reversible air drill is built tough to withstand years of heavy use. High precision chuck. Bakelite rotor blade. P6 industrial bearing,long working life. Composite with glass fiber body, light weight and not easy to be deformed in low or high temperature. Rotor have be heat treated by Ipsen which import from Germany.

Composite housing, light weight helps avoid fatigue during prolonged use. Variable speed throttle for easy starts. Precision machined gearing ensures maximum power transfer and durability. Rear exhaust directs air away from work piece. Variable-speed trigger for precise speed control. One hand push button forward/reverse controls.

Ideal for home improvement projects, body work installation and repair, farm implement assembly and repair, construction, metal or wood fabrication, general equipment, and auto repair and maintenance.

Model No:RP17101

Grinder cap:3/8"

Free speed Rpm:1800

Air inlet(NPT):1/4"

Air hose(ID):3/8"

Overall length:6.69”(170mm)

Net weight:2.07Lbs(0.94kg)

Avg. air consumption:4cfm

Sug. air comp:2HP

RONGPENG has quickly risen to become an unrivaled global producer of air-powered devices including air tools, air spray gun, air nailer, airless paint sprayer, and etc.

RONGPENG seeks independent sales agent to represent and market our industry-leading pneumatic tools. We support OEM, ODM, OBM customization, small order quantity is acceptable and samples are available.

Make any cooperation possible. Any services related to the product, inquire with us now! Rongpeng@Rongpeng.Com